|  |  |

|---|---|---|

|  |  |

|

Types of calcium scaling:

Calcium carbonate is a common type of scaling that forms white deposits on pool surfaces, including walls, railings, and ladders. Although challenging, it is manageable.

Calcium silicate scaling forms more slowly and is extremely difficult to remove. Suspected calcium silicate buildup may also indicate pipe buildup.

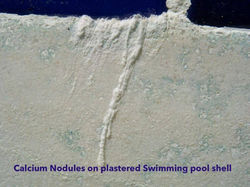

Calcium nodules are small, hard deposits that appear on the pool surface as tiny white or grey bumps.

To distinguish between these types, place a drop of muriatic acid on the scale. If there is a reaction with foaming, it is calcium carbonate; if there is no reaction, it is likely calcium silicate.

Factors Contributing to Calcium Scaling:

High Calcium Levels:

Scaling can occur when water has calcium levels exceeding 400 ppm (parts per million), which is common in areas with hard water.

Water Chemistry: An environment conducive to scaling is created by high alkalinity and pH levels.

Water Temperature: Scaling is intensified by higher water temperatures.

Causes of Calcium Silicate Scaling:

Calcium silicate scaling in swimming pools results from several factors:

When the pool surface is installed, the scaling may relate to the silicate amount in the mix, neglecting water chemistry protocols, and not brushing the surface for the first month after filling with water.

High calcium levels can stem from hard water or using calcium hypochlorite shock, which increases the water's calcium content.

High alkalinity and pH levels provide an ideal environment for calcium scaling.

Elevated water temperatures can also lead to calcium scaling.

Causes of Calcium Nodules:

Calcium nodules are small, hard deposits that appear on pool surfaces, often as tiny white or grey bumps.

These are generally caused by an overabundance of calcium carbonate in the pool water, leading to accumulation and hardening on different surfaces.

Here are the factors contributing to calcium buildup in pool interiors:

Calcium Carbinate Scale

Calcium Carbonate. This type of scaling is relatively easier to remove. It occurs when calcium hardness levels in the pool water are high

Calcium Silicate Scale

Calcium Silicate: This type forms more slowly but is extremely challenging to remove.

Calcium Nodules

Calcium nodules in swimming pools are small, unsightly bumps that can form on plaster, fibreglass

Chemicals Required

Chemicals required to perform the required treatments

Calcium Scaling:

Billabong Pool Service employs various treatments to tackle the challenging issue of calcium carbonate scaling. Before proceeding with any treatment, the service technician must assess several factors:

-

The severity of the scaling and the duration it has been left untreated.

-

The nature of the scaling and the surrounding pool environment.

-

The sanitation and filtration systems in use.

-

The existing water chemistry.

Calcium Carbonate Scaling

Here are some examples of scaling

|  |  |

|---|

The common approach is to use chemical treatments to dissolve calcium carbonate deposits, but one or all of the following treatments may need to be used to address this issue:.

-

Consider adding a chemical sequestrant to the pool water. This helps prevent the formation of new deposits and may even reduce existing ones.

-

Lower Calcium Hardness: Partially drain and refill the pool water to reduce calcium hardness.

-

Manual Removal: Scrub the scaling using a pumice stone or a stain eraser tool.

Chemical Treatment:

-

Establish the water chemistry and, if possible, the water chemistry history of the pool.

-

The parameters to consider are pH and T.A. (total alkalinity), as they are the most important in proceeding with a treatment.

-

Aim for a pH target of 7.0 and total alkalinity (T.A.) below 100 ppm but not less than 60 ppm. If the severity of scaling warrants it, consider an acid bath with the existing water at a rate of 10 liters of undiluted acid per 50,000 liters. Note that this will significantly lower both pH and T.A. levels and should be used only briefly, from 24 to a maximum of 48 hours, to soften the deposits. Afterward, strive to achieve less aggressive pH and T.A. levels.

-

The calcium hardness level should be established to provide a base point, recorded, and referenced after treatment has been performed.

-

To soften the scaling, products like Lo-Chlor Stain and Scale Attack Parts 1 & 2 have proved effective in softening and subsequently removing light to moderate scale.

-

Heavy scaling may require multiple treatments and more aggressively low pH levels for prolonged periods of time—weeks, possibly months.

-

Manual Removal: Scrub the scaling using a pumice stone, stain eraser sticks, or metal algae brush to help loosen the softened scale.

-

Testing of calcium hardness needs to be performed at this stage to establish that the calcium level has increased from the baseline established before the treatment started.This will indicate the removal of calcium from the surface and the success or failure of the treatment.

-

A sequestering agent like Lo-Chlor Stain & Scale Defense, Lo-Chlor Aquaguard, or Riversands CalStop is used to retain the removed calcium in solution.

-

Filtration should be addressed at this time, and a regular filer-clean schedule of every 2 days should be in place at least a week after treatment.

-

If a cartridge filter is being used, the condition and effectiveness of the filter need to be assessed, and a replacement may need to be considered.

-

If a sand filter is in use, you should consider using Lo-Chlor Filter Aid & Metal Remover.Partially draining and refilling the pool water to reduce calcium hardness may be required at extreme levels of calcium hardness.

-

Re-balance the pool, continue to monitor calcium hardness levels, and continue removal protocols until it reaches between 180 ppm and 250 ppm.

* Use a pumice stone or a tile brush to gently remove the scaling from pool walls, tiles, and other surfaces.

Be cautious not to damage the pool finish while scrubbing.